Project: "The TurboMotor roary-blade engine"

1. Our revolutionary invention is the "Turbomotor"

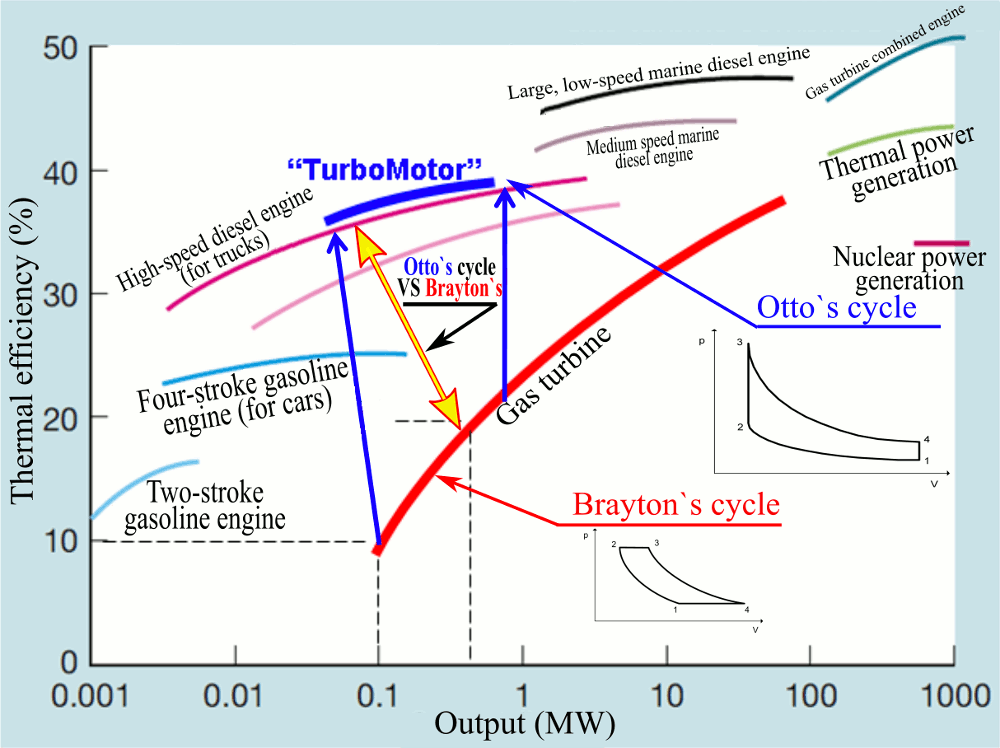

We proposed an effective solution to the problem of increasing the thermal efficiency of gas turbine ICE of low power (up to 1 MW) from 2 to 3 times

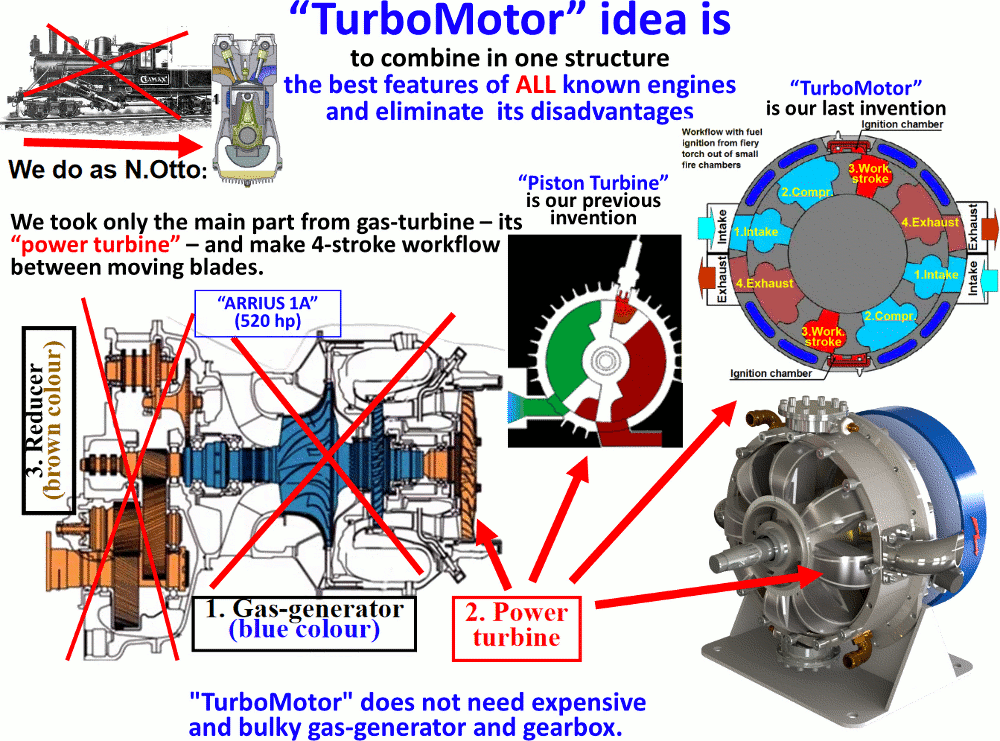

The idea of the "TurboMotor" is to combine the qualities of the rotary kinematics of a gas turbine (to obtain a high specific power) and several closed working volumes of a piston engine with a large peak gas pressure (to obtain a good fuel saving).

Modern transport requires very powerful, light and economical engines. But there are no such engines today. So, an invention was made for the revolutionary improvement of low-power gas turbine engines (GTE, for power less than 1 MW) by replacing the conventional for GTE workflow of Brayton cycle (in the flow of air without increasing the pressure during fuel combustion) by Otto cycle (in a closed volume with increasing pressure at combustion of fuel) and our patents US8210151 B2; US8511277 B2; US8950377 B2. The result of this innovation is an increase in the thermal efficiency of a low power GTE by 2-3 times and a large specific power of the engines (≈ 3 kW / kg) similar to GTE power. Engines with such parameters can already provide a vertical takeoff and landing, as well as a sufficiently high speed of vehicle flight between settlements.

(based on: "Approach to High Efficiency Diesel and Gas Engines", by Tatsuo Takaishi and others) local copy.

2. Nothing is new ...

Basically, we do what the inventor of piston internal combustion engine (ICE) Nikolaus Otto did a century and a half ago. He took the locomotive as the prototype, but threw away the most bulky of its units - the steam boiler and the furnace - and began to implement the entire thermal working process directly in the cylinder. Similarly, we take a gas turbine engine for a prototype, but we throw out its most bulky and expensive aggregates - a gas generator and a high-speed reducer, and the entire thermal work process is carried out between the blades of the power turbine. But the blades of such a turbine have a rotational-vibrational motion under the influence of a special kinematic mechanism - a simple and reliable.

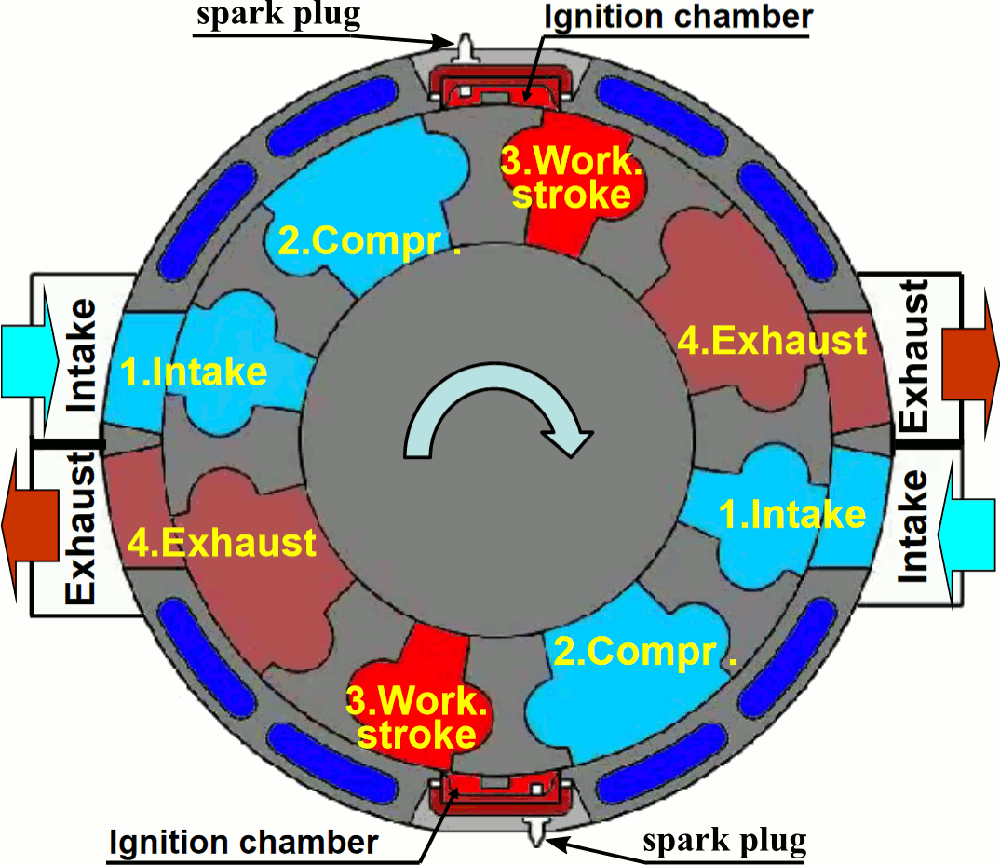

3. The "TurboMotor" operation principle

The uniqueness of the mechanism for driving the rotors is that all its elements are statically balanced, similar to the GTE rotors. The uniqueness of the working process lies in the fact that all cycles of a discrete 4-stroke work process are carried out with constant burning of fuel in permanently hot chambers outside the working cavity under excessive pressure and without forced interruption of combustion. All this is clearly shown below, and also disclosed in the description of our patents, for example: US8210151 B2; US8511277 B2.

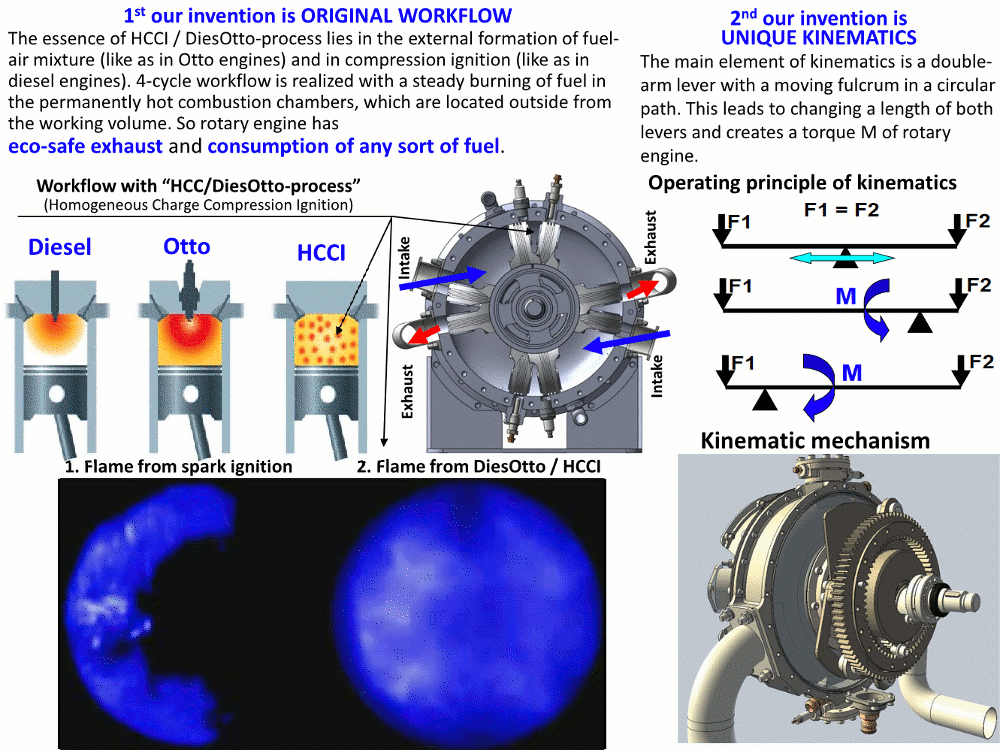

4. Two inventions for one ICE

Two inventions are realized in our rotary-blade engine. It was named The "TurboMotor":

The first invention is the creation of a patented rotary kinematics for a modern ICE by the fusion in the single critical detail of the kinematic mechanism 3 greatest inventions of mankind (see patent US8210151 B2):

- 2-arm Archimedes lever;

- The wheel itself

- Tooth of gear -

- for providing rotational-vibrational motion of 2 rotors which have blades.

The second invention is a hybrid work cycle which combines the positive qualities of 2 different work processes (see patent US8511277 B2):

- Brayton`s cycle - constant burning of fuel in a special external small combustion chambers which have constant excess pressure (to ensure the reliability of the ignition of fuel mixture);

- Otto`s cycle - combustion of fuel in a closed volume between rotating blades with a significant increasing of working gas pressure (to ensure a good saving of the fuel)..

The result is a fusion of the electric drive (for fuel saving and eco-safe operation in cities) and very powerful "TurboMotors" (for vertical take-off and landing, as well as for high-speed flight), in order to combine in single unit the best qualities of 3 different types of engines :

- Rotary kinematics - from gas-turbine ICEs;

- Several closed working volumes - from piston engines;

- Electric motor / generator with power electronics and battery pack - from electric drive -

- this is the Integrated Engine (briefly - the IntEn), which combines in a single unit all 3 design features of different type engines.

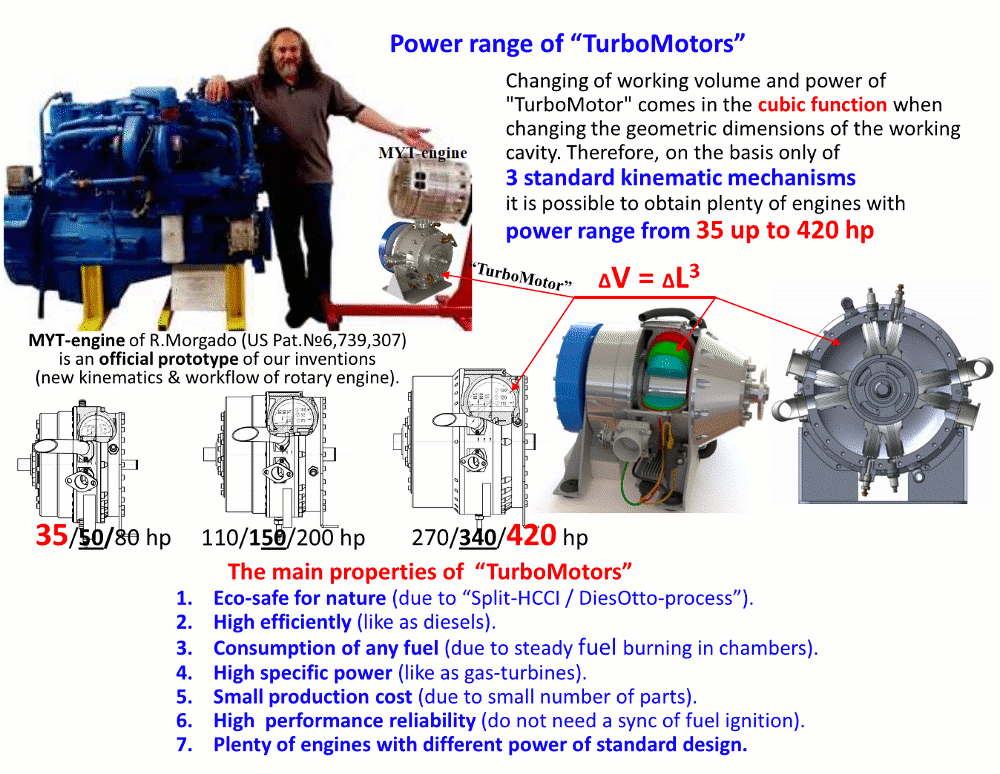

5. Secrets of the "TurboMotor"

The peculiarity of the TurboMotor`s design is the presence of several working volumes in one working cavity, the volume of which determines the power of the ICE. This means that with an insignificant increase of the TurboMotor`s linear dimensions - its working volume and, accordingly, power increases in cubic dependence. It is enough to have 3 standard sizes of "TurboMotors" for obtaining power from 50 to 320 kW

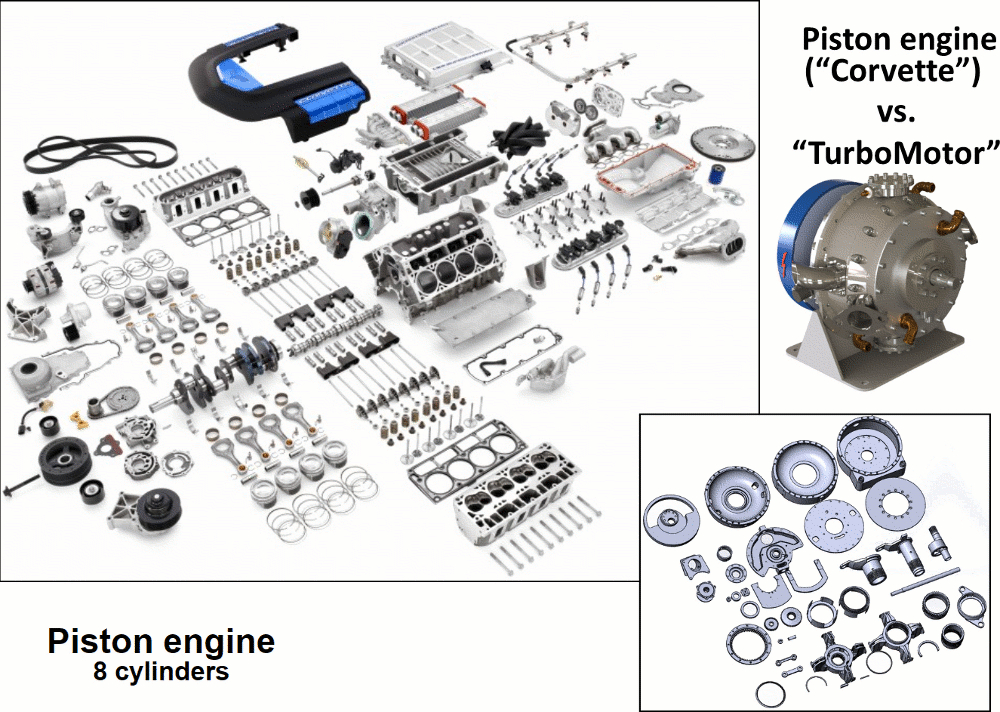

6. The 3-fold effect: compact, lighter, cheaper

The main disadvantage of piston ICEs is the presence of several cylinders. This is the result of the fact that each piston requires an individual kinematic drive plus several valves (gas inlet and outlet). Moreover, a heavy and bulky crankshaft is one for all pistons. A simple, compact and reliable kinematic mechanism controls the movement of 16 ring "pistons" at once in the rotary-blade ICE. The result is obvious - 3 times less the number of parts. Accordingly, smaller dimensions, weight and cost of manufacture.

7. The goal is achieved!

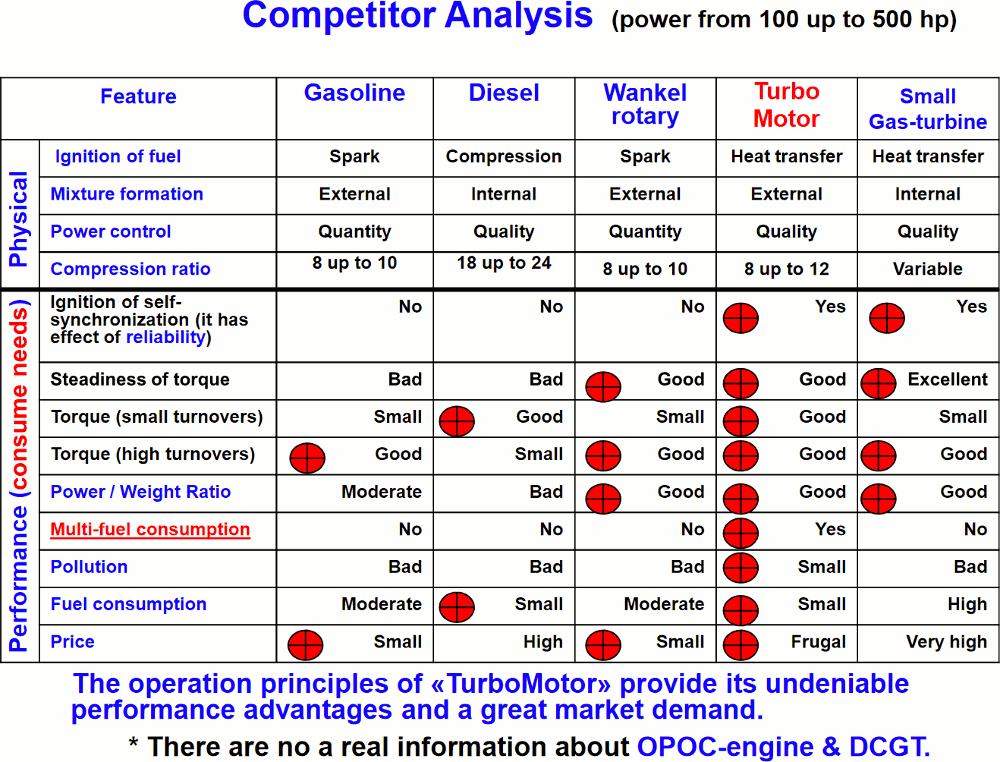

The main types of ICE are shown in tabular form in the figure, and their main positive qualities is indicated by red marks. As a result, "TurboMotor" collected all the positive qualities which are mentioned here. For this reason, we believe that the goal originally set by us for creating a hypothetical "optimal" ICE has been achieved!